Research & Development Facilities

Dycem supports the safety and reliability of research and development (R&D) facilities by providing a highly efficient and effective solution for laboratory contamination control at the floor level. With Dycem, uphold the highest standards of laboratory excellence, secure accurate results, and create an environment conducive to innovation and scientific discovery.

Where to use Dycem in Research & Development Facilities

Biosafety Laboratories.

Animal Facilities and Vivariums.

University Laboratories.

Research Laboratories.

Laboratory Work Benches.

Contamination: The Risk in Research & Development Facilities

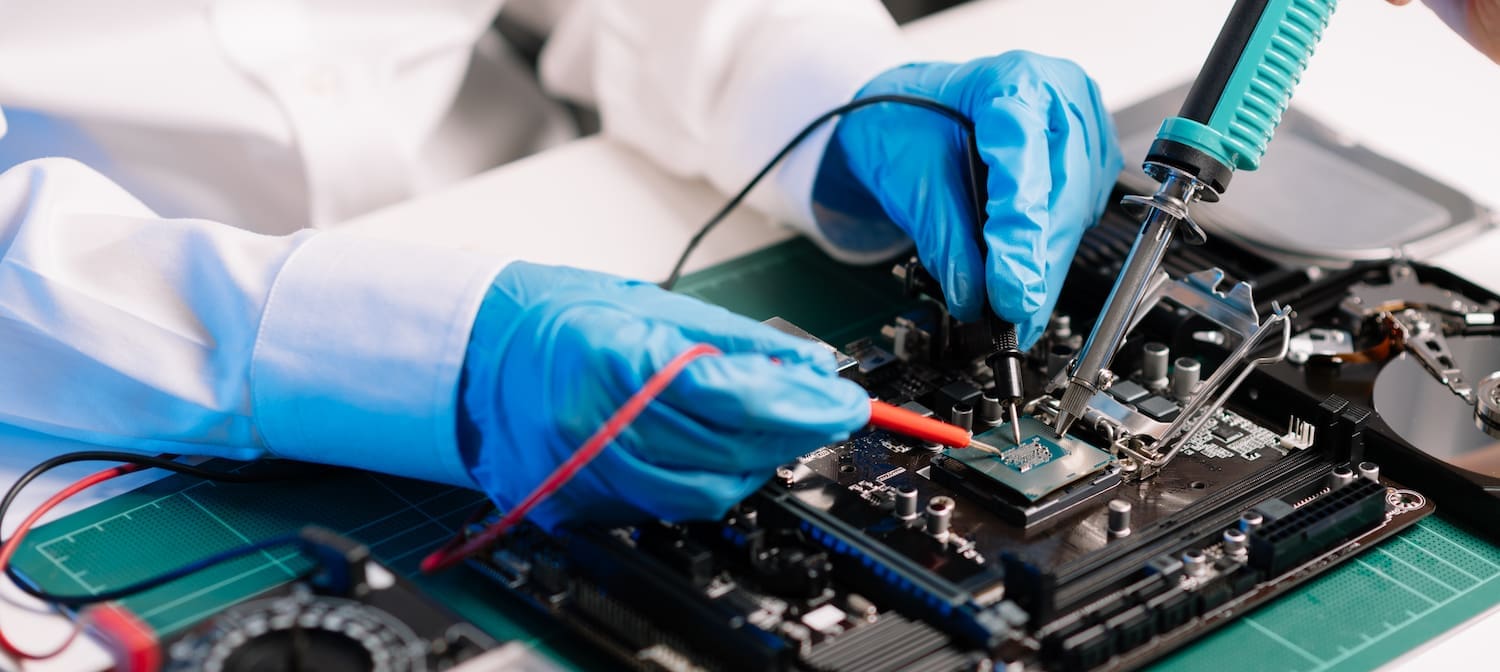

Maintaining a controlled environment in R&D facilities is crucial for several reasons, including receiving accurate and reliable results, personnel safety, sample purity, and compliance. R&D facilities, such as laboratories, must adhere to proper contamination control guidelines to prevent contamination in the lab or unwanted particulates from entering sterile areas.

Contaminants such as dust, viruses, bacteria, skin cells, and fungi can pose a significant risk in R&D facilities. In these cutting-edge environments, where precision and accuracy are paramount, even the slightest contamination can compromise results and set projects back significantly.

The risks to a company’s brand, its profitability, and its people are too big to be ignored. Effective laboratory contamination control is essential for facilities to ensure the safety of the devices they produce.

By utilizing Dycem products, R&D facilities can maintain a clean and controlled environment, safeguarding their investments in research and development while mitigating the risk of contamination-related setbacks.

Don't Ignore the Floor...

80% of Contamination Enters a Critical Space at Floor Level.

Benefits of Dycem to Research & Development Facilities

superior floor & Air particulate control

Dirt and dust are captured on Dycem mats and remain on the surface until cleaned off. With Dycem, R&D facilities benefit from a reduction in floor-level particulate of up to 99.9% and a reduction in air particulate levels of up to 75%.

REDUCED MICROBIAL CONTAMINATION CONCERNS

With Dycem mats installed prior to critical areas, our R&D customers have peace of mind that damage from microbial contamination is minimized. All Dycem products contain Biomaster, an active antimicrobial additive.

COST-EFFECTIVE, SUSTAINABLE ALTERNATIVE

Unlike disposable contamination control solutions, Dycem mats last on average 3+ years. R&D facilities typically see an ROI shortly after purchase, as well as the added benefit of a reduced carbon footprint due to less plastic waste.

Our Products, Your Industry

R&D facilities must take every step necessary to ensure a safe and sterile process to protect their research and products. Dycem has solutions to support the many types of processes and the varying quality control needs of the industry. Preventing contamination in the lab and other critical spaces is our priority.

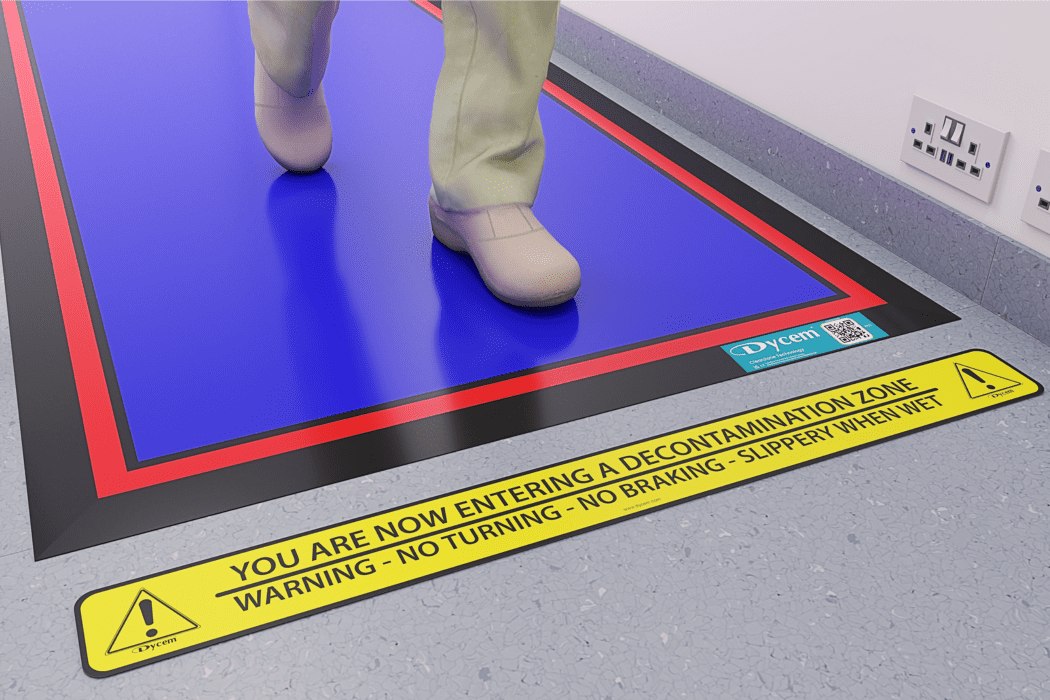

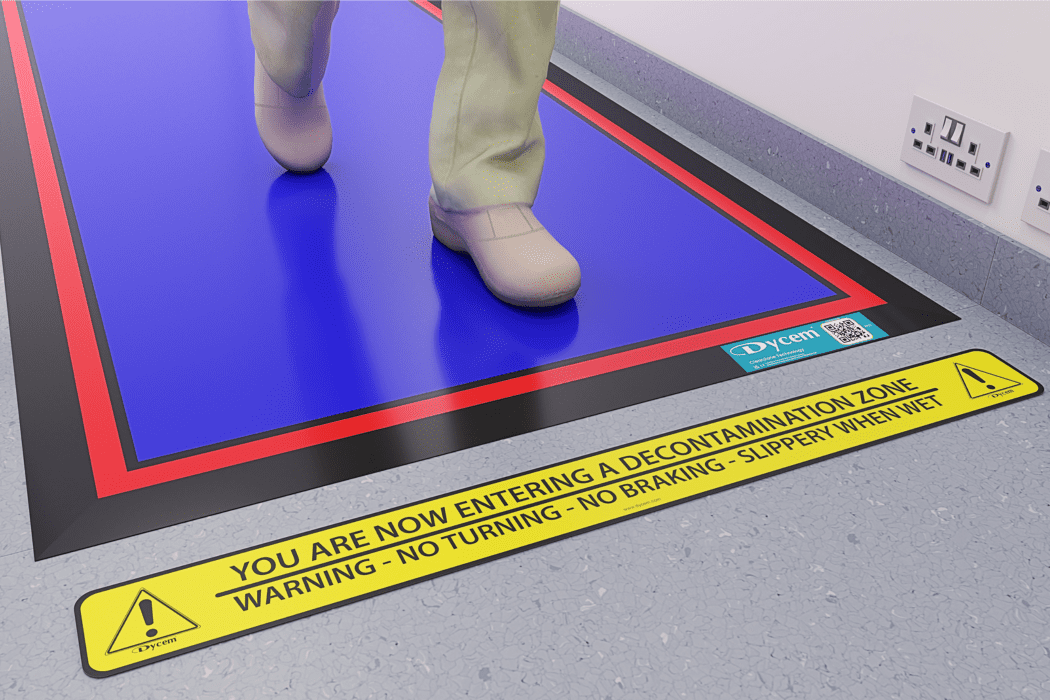

Dycem CleanZone

CleanZone helps control contamination from the shoes of personnel.

Dycem Floating Mats

Floating Mats are a contamination control solution that can be moved as needed.

In Your Industry

Discover your industry’s specific applications—all conveniently summarized right here.

Success Stories...

Discover our success stories in your industry.

Learn how our customers have benefitted from installing Dycem.

Three Ps of Quality Management in R&D Facilities

Read some of the following best practices for maintaining a clean and safe lab environment:

Some of the most basic laboratory procedures are the most important, including using proper aseptic technique, wearing clean lab coats, and washing hands in order to reduce the risk of introducing microorganisms into the laboratory environment.

Make sure that laboratory floors are cleaned regularly. The U.S. Centers for Disease Control and Prevention (CDC) recommends that lab floors be wet mopped at least daily in a biohazard area.

Dust can contain mold and other airborne contaminants that can potentially interfere with lab testing, especially in microbiology labs. This is one reason why non-exhaust fans should not be used in laboratory settings, fans in the lab can circulate those airborne contaminants.

Dycem Contamination Control Mats fit into standard biosafety SOPs and aid with the disinfection processes that are fundamental in complementing the safety of risk management measures. Dycem captures and retains up to 75% of airborne contaminants and prevents them from entering critical areas.

Utilizing standard precautions and correctly employing Personal Protective Equipment (PPE) are essential to ensure laboratory personnel safety.

Ensure that laboratory safety equipment such as emergency eyewashes, showers, and fire extinguishers are unobstructed at all times. Electrical panels in the department should have three shoes of clearance in front of them.

Check all lab electric cords as well for fraying or other damage. Ensure that compressed gas tanks are secured to prevent tipping.

A career in a laboratory setting involves working with complex procedures and hazardous materials.

Regulatory agencies, and common sense, demand that staff can work safely every day. Staff must be educated on the proper use of lab equipment for effective infection prevention in the workplace. Facilities should complete an assessment of the physical laboratory workspace, correct any issues discovered, and educate staff to prevent reoccurrences. Once the physical lab environment is in safe order, it is time to ensure that features are in place that will help staff maintain safety in the event of an accident.

Learn more about Good Laboratory Practices

Good Laboratory Practices CEU accredit course with Veeva Systems:

“Not everyone who works for a laboratory performs analytical testing, but every single person plays a part, no matter the role. For this reason, it’s crucial to understand what GLP is, why it’s so important and how your role impacts GLP compliance.”